Quality Control

We adhere to international quality standards throughout every stage of production to ensure high precision, consistent performance, and total customer satisfaction.

Dimensional Inspection

Material Testing

Non-Destructive Testing (NDT):

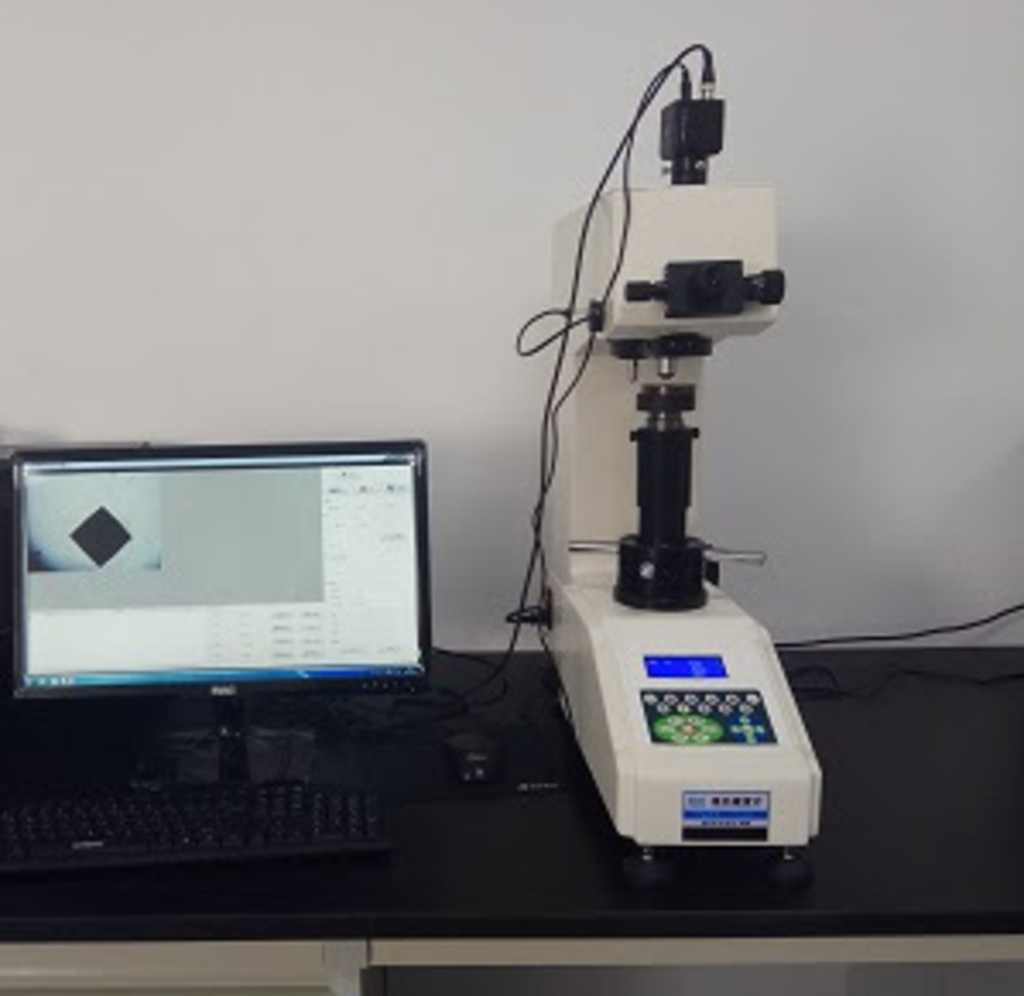

TestinHardness Testing (HB, HR, HV)

Metallographic Examination (grain structure, micro defects)

Alternating salt spray test