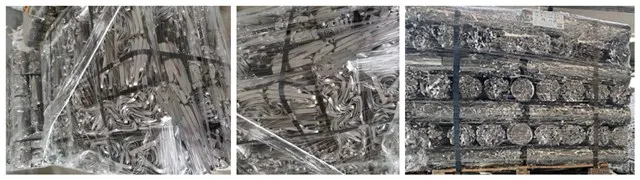

Product

SW precision metal

S.W is a full-service custom precision casting products manufacturer offering end-to-end customization, from mold development and prototyping to mass production and packaging. S.W. already customized more than 2000 custom casting products projects for our partner in the past 16 years with much experience in casting products technical solution. S.W. serves a wide range of markets, including nuclear power stations, fluids & chemicals, instrumentation & metering, food, high-speed rail, marine equipment, green energy, automotive, Oil & Gas, medical, industrial locks, power, construction hardware, aerospace, gas turbine, etc. The custom steel casting products include:

Customized precision casting products

We already customized more than 1000 casting product projects for our partner in the past years with much experience in casting product technical. The custom casting products include:

The Features of Precision casting Products

About S.W

S.W team work with the different industries brands Owner, products development managers, products managers, products designers together and offer them OEM ODM solution from molded casting products design, prototyping to casting products contract manufacturing, marking, package to ensure their casing projects success.

Why Choose S.W as casting Product Supplier

16 years’ custom casting products experience

Safety Factory

100% raw material

One Stop Service from design to whole process manufacturing

Stable production capacity

Wholesale OEM/ODM Services

Strict Quality Control

Premium quality products