About s.w

SW Precision Metal成立于2008年,是一家一站式定制铸模产品制造商和铸模产品加工解决方案成立,专注于铸模产品领域。公司已通过TS 16949:2016和ISO 9001:2015我们为合作伙伴提供从创意到上市的全程支持。我们是领先的铸模产品品牌和最终用户的首选合作伙伴。我们生产的铸模产品适用于 汽车、建筑、医疗设备、造船、食品机械、采矿、安全防护、石油化工等各行各业。我们因提供创新的定制铸模产品、制造专业知识和技术方案而获得认可。

s.w Custom casting Products service

How to work with SW?

From initial casting products design to final delivery, we provide comprehensive one stop services. You do not need deal with multiple suppliers or coordinate different aspects of the project yourself. Simplify the entire process and save your valuable time.

Confirm requirement

Choose the existing style or Design Drawing. according to you needs and get our Engineer Support.

Cost Evaluation

S.W offer the quote according to your design, quantity and other specific requirements.

Prototype and Tooling

Once you approve the quote and make the payment, production will begin from prototype, tooling.

Mass Production

Prepared casting Material according to your Pouring and Cooling, Cleaning, Machining And First Quality Inspection, Heat Treatment, Surface Treatment, Quality Inspection and Packaging.

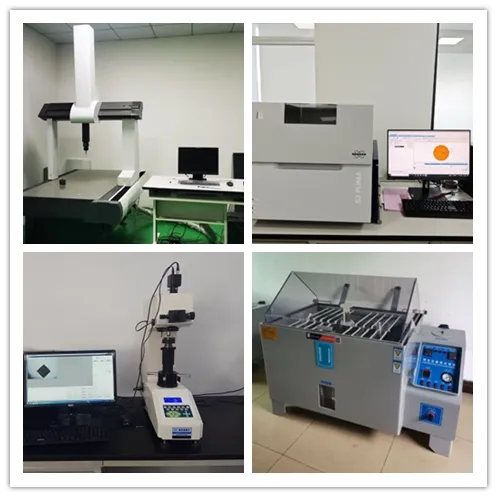

Quality Inspection

S.W perform multiple rigorous tests throughout the manufacturing process to ensure that the quality of the product meets expectations when it leaves the factory.

Afterservice

S.W established and improved the after-sales system, timely and comprehensive grasp of customer information, and achieved timely service contact and coordination to slove the aftersevice problem your ocured.

Why Choose S.W as CASTING products Supplier

16 years’ experience

Rich market experience makes us familiar with the products and market requirements of different wholesale customers

Safety Factory

S.W is certified by TS 16949:2016 and ISO 9001:2015. The third parties and the world’s Fortune 500 companies have helped you verify the factory strength and reliable for you.

100% raw material

We work with a wide range of high-quality metal raw materials to meet the diverse needs of different industries and applications. Our materials are carefully selected and strictly inspected to ensure excellent performance, durability, and casting quality.

One Stop Service from design to whole process manufacturing

We operate our own foundry and machining shop. All the casting products cycle under one roof- from designing products & building tooling to launching into full-blown production. You will reduce the risks of working with multiple vendors, save your time to market & lower costs.

Premium quality products

We provide high-quality metal components with excellent mechanical strength, precise dimensions, and superior surface finish. Each part is manufactured using certified materials and undergoes strict quality control to ensure performance and durability.

Wholesale OEM/ODM Services

S.W complete OEM/ODM Services provides a variety of wholesale customization services to suit customers’ different designs and product needs. Customized service for design, Surface Treatment, packaging.